Our Manufacturing Factory:

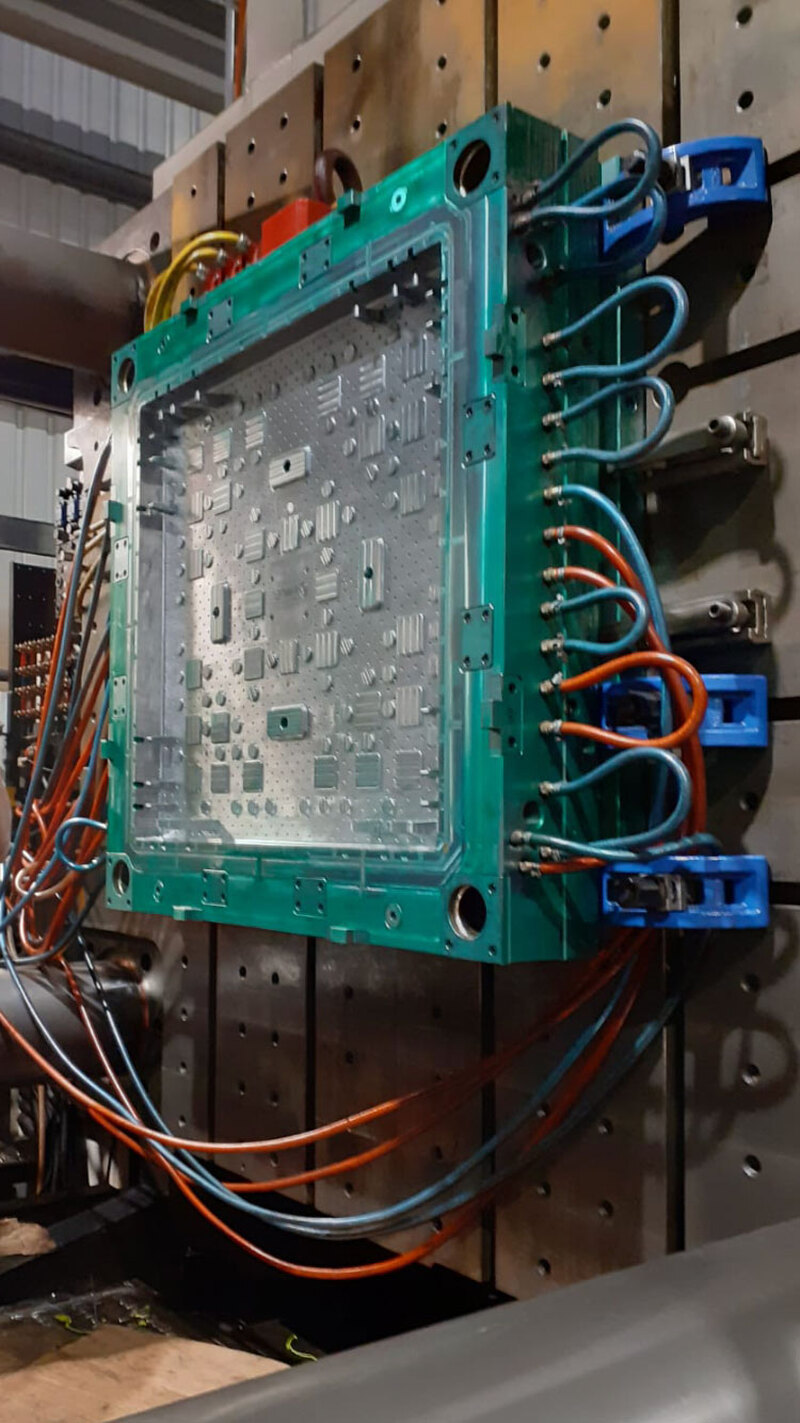

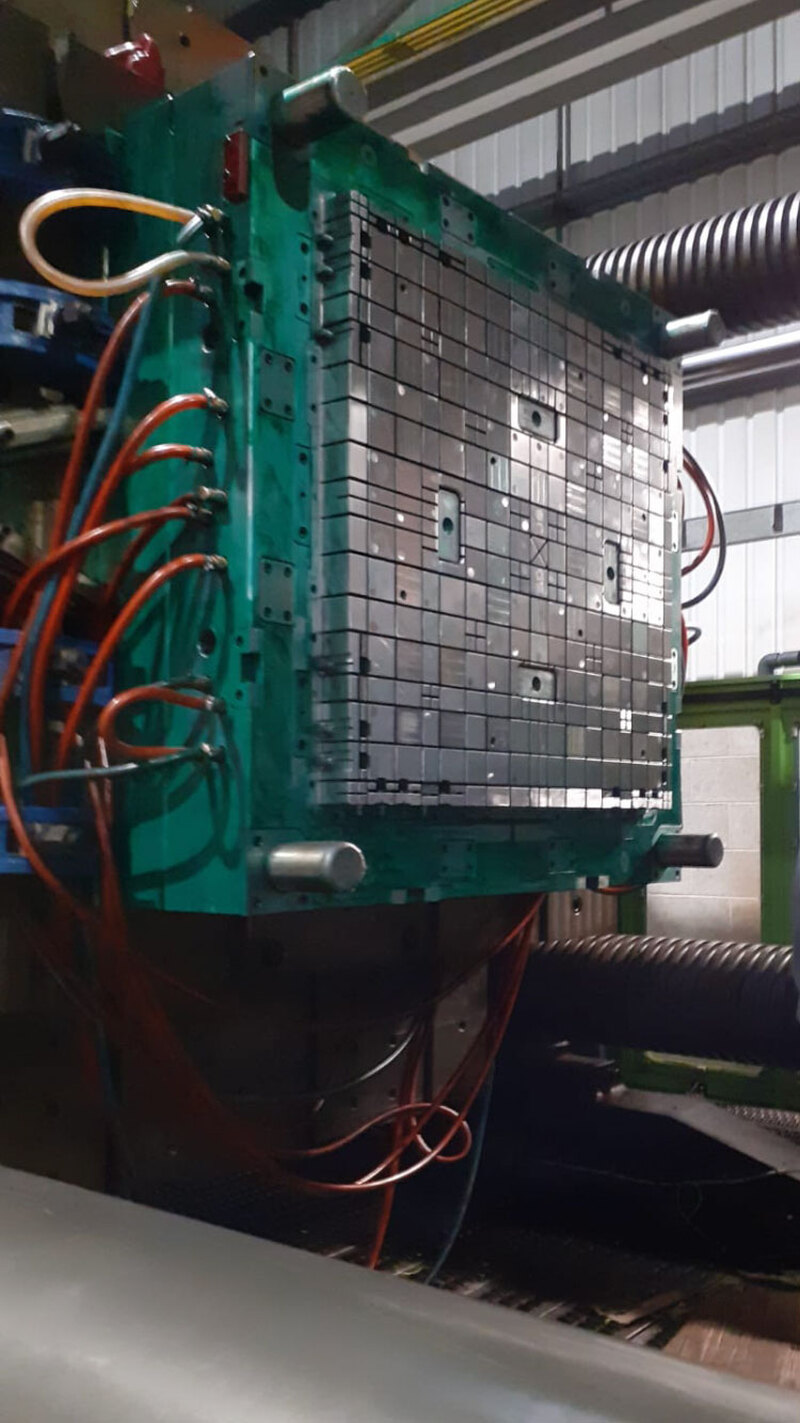

Our manufacturing factory has more than 30 years experience in the plastic injection moulding industry and has strong partnerships with specialised designers and mould makers covering everything from the conception to final production.

Our manufacturing capability of more than 10 machines ranging from 40 Tons to 2700 Tons allows us to supply components from 1g up to 20kg in a wide range of materials and for a range of different industries.

Manufacturer quality system – ISO9001:2015 certified – ensures that our clients receive the high standard of service that they deserve.

Manufacture

- Designed and made in the UK

- Bespoke tooling, incorporating the latest manufacturing technology

- Can be provided in specific colours and with clients personal logo if required

Speed of Installation/Dismantle

- 2 men can install over 100m2 per hour

- Much quicker to install than metal decking systems and birdcage scaffolds

- Competent trained operatives can install it; you do not need to be a scaffolder

- The installation of the decking occurs from below so there are no working at height disadvantages

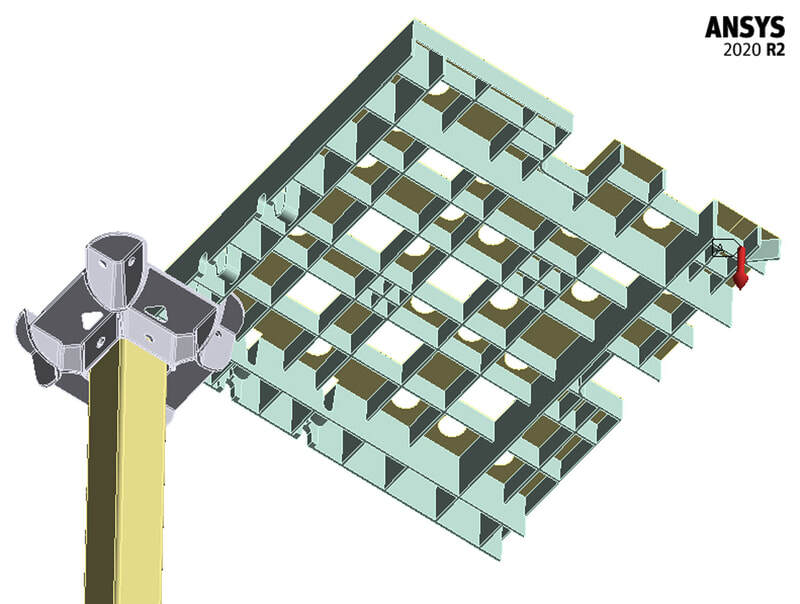

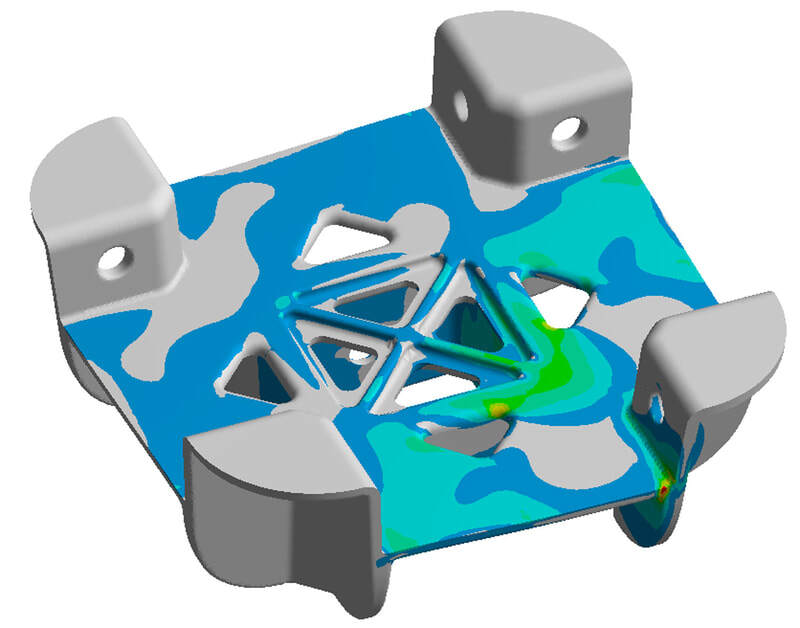

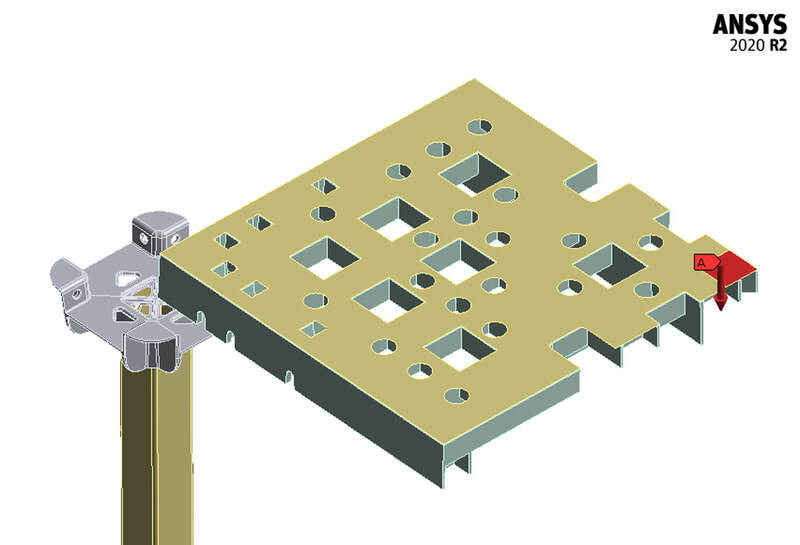

Utilised static and dynamic FEA using ANSYS Mechanical Workbench and considered linear and non-linear material behaviour for a plethora of damaging load cases. In all instances the Sandec platform exceeded the relevant safety requirements and the FEA was validated using physical testing”

Lightweight

- The SANDEC platform is an extremely robust and lightweight design. We have tailored the platform to be one of the lightest on the market at XX kg and ensured that it meets all design standards and regulations, including:

- BS EN 12811-1:2003 Temporary works equipment. Scaffolds. Performance requirements and general design.

- Although the SANDEC platform was design with temporary works in mind, it also meets the requirements of working platforms and walkways, as defined in:

- BS EN ISO 14122-2 Safety of machinery — Permanent means of access to machinery -- Part 2: Working platforms and walkways

Transportation & Storage

- The panels are stored flat and can be stacked 26 high for transport meaning 26m2 can be stored within a 1m2 space on site when not in use, or waiting to be used

- The legs are stored in simple stillages, which have a capacity of over 100 in each stillage

- The panels are designed to be forklift friendly

- They can be left stored outside in all weather conditions without affecting the product

Versatility

- Suitable for timber frame as well as brick and block house construction

- The design is carefully thought through with holes in the panels allowing for easier manual handling

- These holes in the deck panels also allow scaffold poles to pass through them

- The panels can be pressure washed or steam cleaned without affecting the product stabilities

Safety Tried & Tested

- Achieves the HSE proposed height safety hierarchy requirements

- We have taken our level of testing beyond the requirements of the published design codes and commissioned extreme physical testing by renowned academic institutions, where the following loads were applied, without any damage to the platform

- 1,000 kg four point load applied to the centre or each platform and axially in line with the legs

- 9 off impact tests of 539 J: 3 off tests in the middle, 3 off tests over one leg and 3 off tests at the edge of adjacent platforms

- Sturdy appearance and construction provides users peace of mind, improving work output

- Patterned face provides traction and a secure grip for users

Strength

- Same load capacity as general use scaffold 200KN per m2

- Can be loaded on, doesn't need additional propping underneath

- The SANDEC platform has been designed from the outset with safety and ergonomics of the user in mind. We have utilized advanced Finite Element Analysis (FEA) using ANSYS Mechanical Workbench to fine tune our design, to enable exceptional strength to weight characteristics

- All components are manufactured from UV considerate materials

- Resistant to oil, diesel, petrol and other similar chemicals

- Locking pins for safety and fixed stability

Cost

- Maintenance free with no mechanical parts

Contact Us

Telephone: 01228 791 896

10 Bridge Street, Longtown, Carlisle, Cumbria, CA6 5UD

Email: [email protected]

10 Bridge Street, Longtown, Carlisle, Cumbria, CA6 5UD

Email: [email protected]